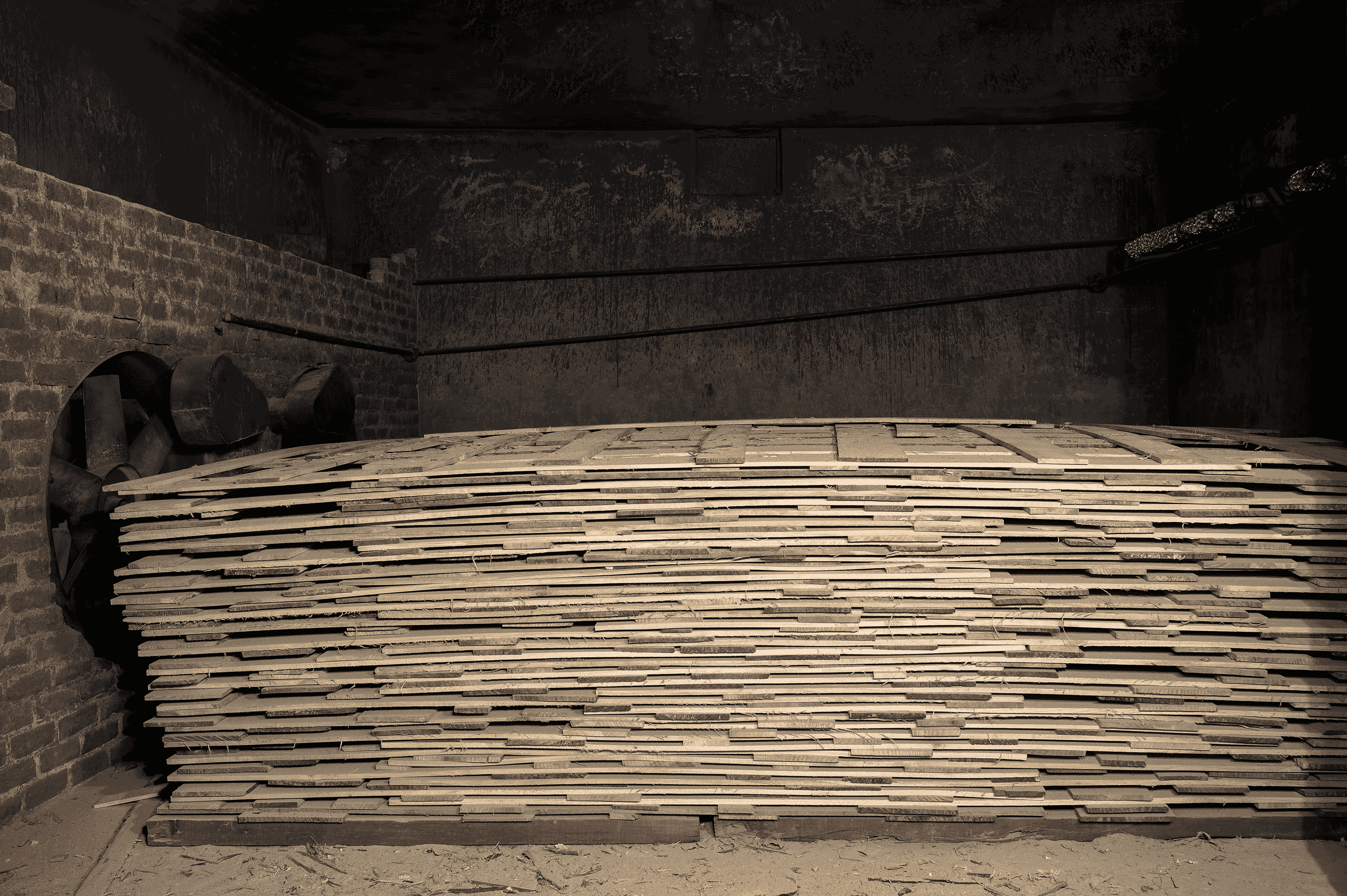

The seasoning Kiln is a chamber equipped with arrangements for heating and dehumidifying the drying air to desired conditions of temperature and relative humidity and its circulation over the surfaces of timber stacked inside. Fans are used for faster circulation of air.

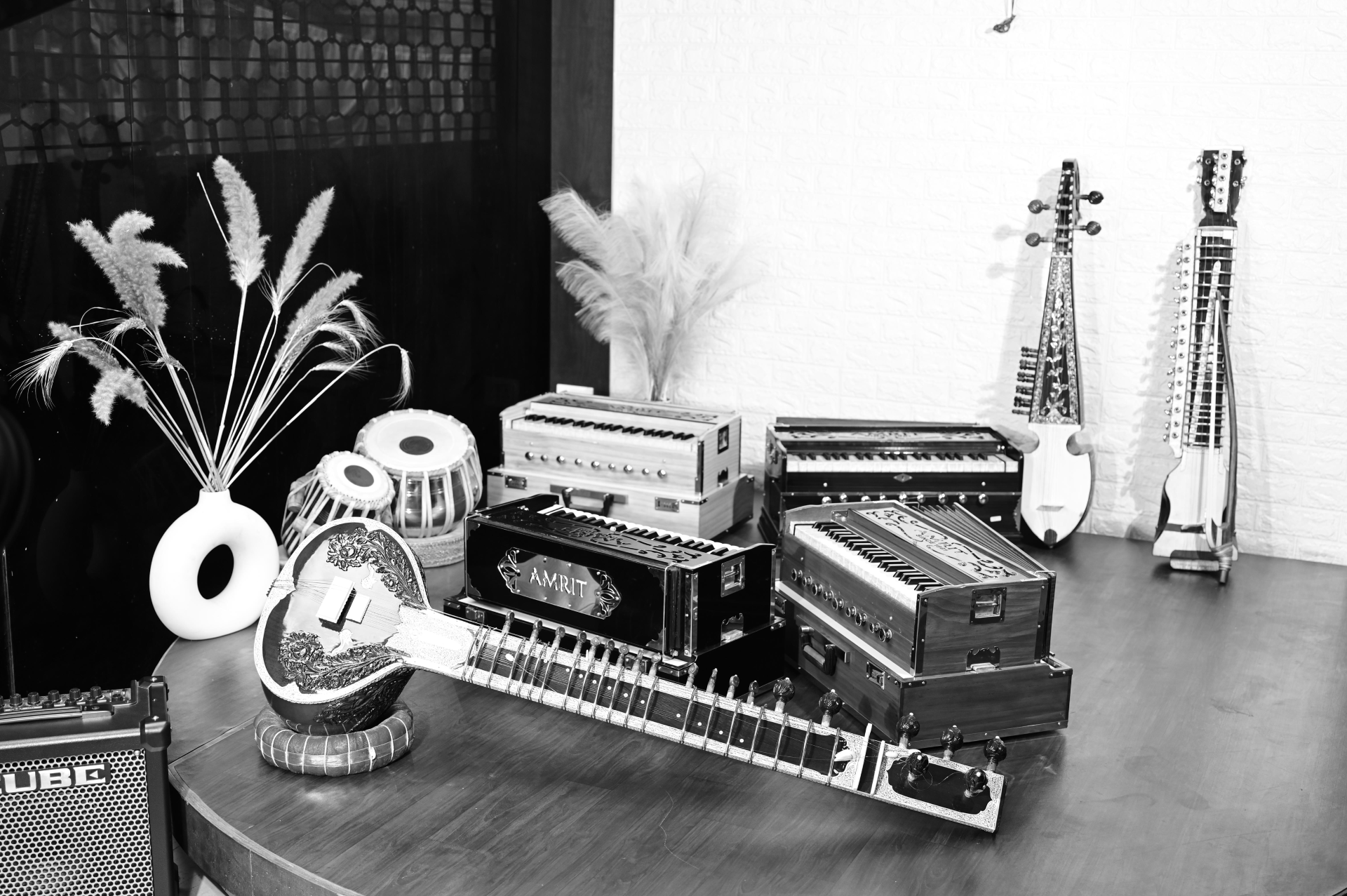

The sounds of the harmonium are generated by freely vibrating metal platelets – the so-called reeds – the same mechanism of sound generation as in the accordion. There is at least one reed for each note. Small air holes are positioned above all reeds, which are closed on top by leather seals like valves. By pressing down a key on the keyboard, the valve above the respective reed opens; the air accumulated inside escapes, blows at the reed and creates a sound. By releasing the key, it will be pressed back into its original position by means of a spring, the valve closes, the air stream stops, and the sound ceases.

The air for blowing the reeds is created by bellows, which in most harmonium models are fitted into the bottom of the instrument, invisible from outside. Visible are however the outer bellows at the back of the harmonium, blowing up the inner bellows using pumping movements and thus building up the required air pressure. Even if there is only little air inside the inner bellows, inbuilt springs see to it that the air escapes with a reasonably even pressure for playing.

Most harmoniums have two or three separate reed sets placed inside in air chambers sealed off from one another. In most cases, the corresponding notes of the reed sets lie in octave’s range to each other. A distinction is made between three pitches: the deep bass octave, the middle male octave and the high female octave. An adjustment of the register at the front of the harmonium allows the selection of a respective air chamber from which the air of the inner bellows should escape. In this way, one or a free combination of the existing reed sets can be used for playing.

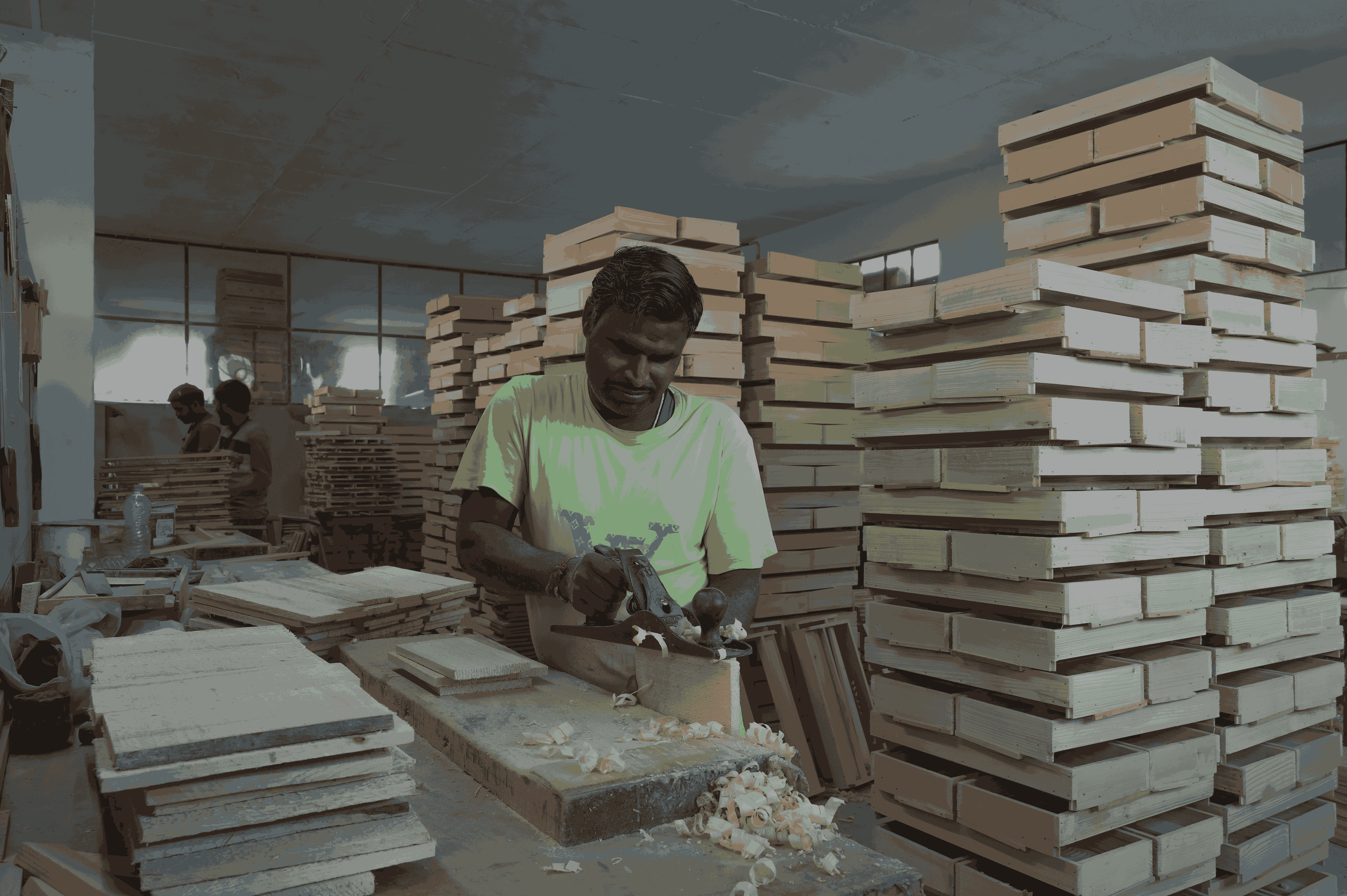

The outer frame, inner air chambers and key mechanisms are made from wood. The quality of the wood as well as the precision of manufacturing plays a major role. Bad wood quality or sloppy processing may result in parts jamming, ripping or distorting. Thus unplayable or permanently resonating notes or air loss creates malfunctions.

folds. Leather is also used for the valve seals. Metal is used for screws, key springs, bellows springs, and reeds. The key surfaces are layered with plastic coatings. Visible wooden surfaces are polished with varnish, partly with added pigments, and either polished to high-gloss or semi mat or they are waxed.